Our Control Systems

Frescold Services has perfected its innovative “two-temperature” method as a standard control process.

This state-of-the-art process is unique to Frescold Services —not available from other manufacturers — and offers our customers several benefits without the need for the maintenance intense steam injectors and boilers.

This approach allows for the following advantages:

- Extremely precise temperature and humidity control tolerances, as well as industry-leading chamber uniformity

- Does not require boilers, steam injectors or high purity water.

- The elimination of service problems commonly associated with steam injection systems

- Requires approximately half the energy usage as a standard steam injection system.

- Very low water requirements. Most rooms can operate on less than 1 gallon of water per day.

Since the system maintains a reservoir of water, the unit is capable of operating normally for several days with a process water interruption. The larger conditioners include a filtered UV system to aid in maintaining water purity. A 30 minute quarterly PM will keep the system clean and efficient for many years.

How it

Works

PGC’s method of control is the same for both reach-in chambers and conditioning systems. In short, the environment to be conditioned is controlled at a targeted dew point temperature and then reheated to a specified air tem-perature. This methodology follows a proven technique that maintain¬ing a constant dew point and air temperature will produce a very constant relative humidity.

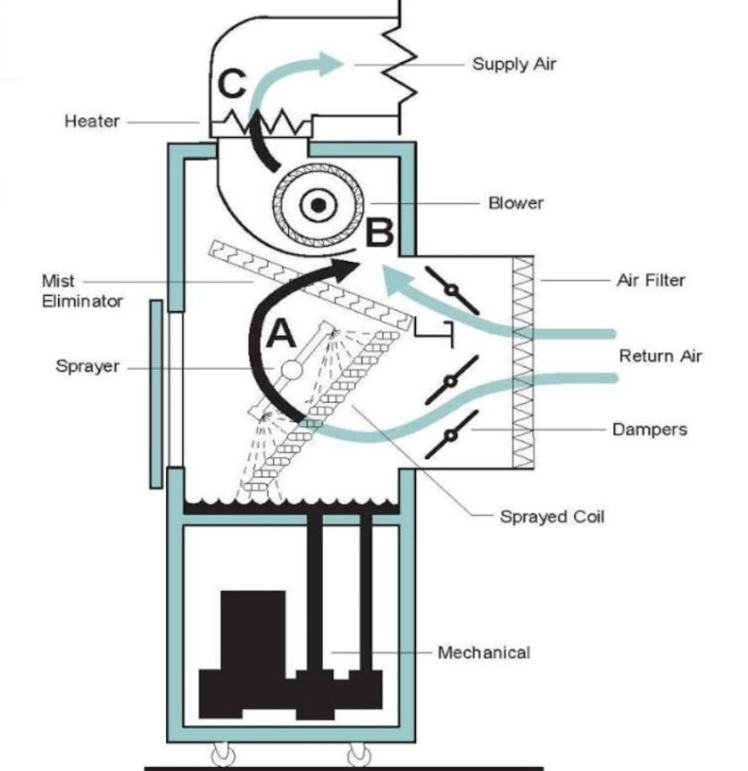

A portion of the air returning from the conditioned area (chamber, modular room, laboratory space) is directed through a water spray area (A), the temperature of which is very closely controlled. The temperature of the water spray is adjusted to maintain the dew point temperature of the targeted condition. As the air passes through the water spray, it is cooled down to the temperature of the water and approaches saturation at that temperature.

The air then leaves the spray chamber through a mist eliminator, which removes any free droplets of water, and is next mixed (B) with air that has by-passed the spray area. After passing over an electric heater (C), to warm the air back to the desired dry bulb temperature, the air is returned to the conditioned space.

Utilising the above method, a very precise humidity control is achieved. The system does not distinguish between humidifying and dehumidifying; it is always setting a dew point and reheating. If the conditioned air has a higher moisture content than the set point, excess moisture condenses out in the cool water spray and dehumidifies the control air. Conversely, if the conditioned air has a lower moisture content than the set point, moisture evaporates from the water spray and humidifies the control air.

The temperature of the water spray is automatically adjusted by the feedback from a high grade RH sensor in the controlled space. If the set point is lower that the actual condition, the temperature of the water spray will gradually decrease until the RH set point is achieved. On the other hand, when the relative humidity set point is above the actual condition, the water spray temperature is incrementally increased until the RH set point is achieved. For conditions that require a below freezing dew point, a desiccant dryer is utilised.

Validation Info

Frescold Services has extensive experience in the development and execution of industry-proven stability chamber validation protocols. Frescold Services can provide and execute stability chamber validation protocols such as Installation, Operational and Performance Qualification.

All temperature data is collected using a Rotronic HW4 Mapping System and digital Rotronic HC2 dual Temperature and Humidity sensors, allowing for temperature and humidity measurements at each mapped point within the chamber. All test equipment calibration is NIST traceable.

Frescold Services provides a complete document package tailored to your needs with each mapping study. We can produce a complete mapping protocol for you, or follow a protocol that you have already created. If you don’t need a full protocol for your mapping study, we can provide a basic validation plan prior to performing the study to specify the mapping details.